John Deere 46R

Hay Pickup

- 4.5 m (14.8 ft.) pick-up features long extended auger flights for smooth crop flow

- Chainless drive for a maintenance friendly drive line

- Compatible with all 8000 Series and 9000 Series SPFH models

Features

R-Series Pickup with 79-cm (31.1-in.) auger diameter and 20-cm (7.9-in.) auger flights

R-Series Pickup with 79-cm (31.1-in.) auger diameter and 20-cm (7.9-in.) auger flights

An unlimited throughput for the 9900 Self-Propelled Forage Harvester (SPFH) was the clear goal during the development of this pickup. This pickup has the largest pickup auger in the industry and can handle enormous amounts of crop with the 79-cm (31.1-in.) auger diameter (6X9 = 56 cm [22 in.]) and the 20-cm (7.9-in.) auger flight. It is built to feed the 9000 Series SPFH to enable new levels of productivity. The large auger levels out lumpy windrows and creates an even crop flow, resulting in improved feeding and increased productivity of the SPFH.

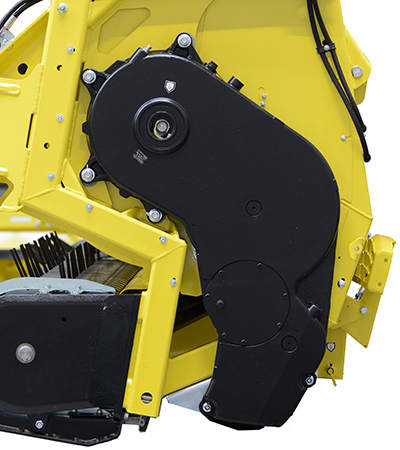

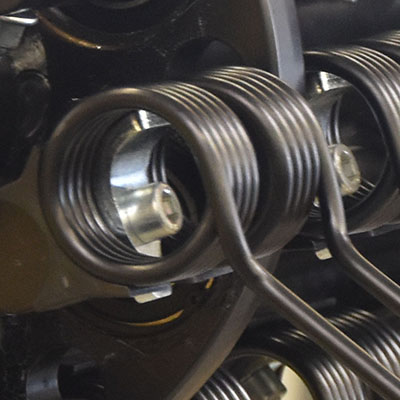

Reliable and durable drive with minimal servicing

Reliable and durable drive with minimal servicing

The 46R pickup featuring the chainless drive reduces the maintenance and repair costs associated with chains and sprockets. There are no maintenance or repair costs for chains and sprockets as on other pickups. The chainless drive makes servicing this machine very easy and does not require any daily maintenance. The operational reliability is further increased along with an increase in customer uptime

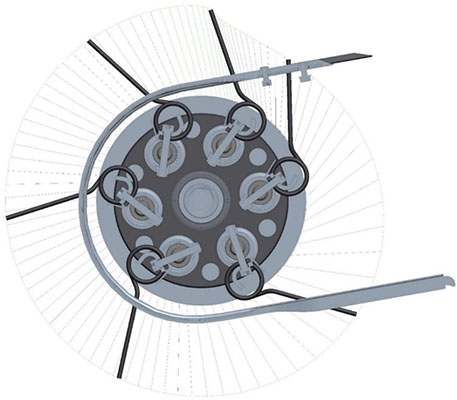

Diagram of pickup reel

Diagram of pickup reel

Pickup reel with six tine bars

Pickup reel with six tine bars

The R-Series Pickups are equipped with six tine bars. The tine size is 6.5 mm (0.26 in.). More tines with more strength ensure a perfect job is always done with no crop left behind, even in high yield conditions. A lower pickup reel speed is also possible, resulting in less wear.

The 6.5-mm (0.26-in.) thick tines are mounted on the tine bars with support elements. These elements distribute the forces better from the tine wire to the bar. This design leads to a longer service life for the tines.